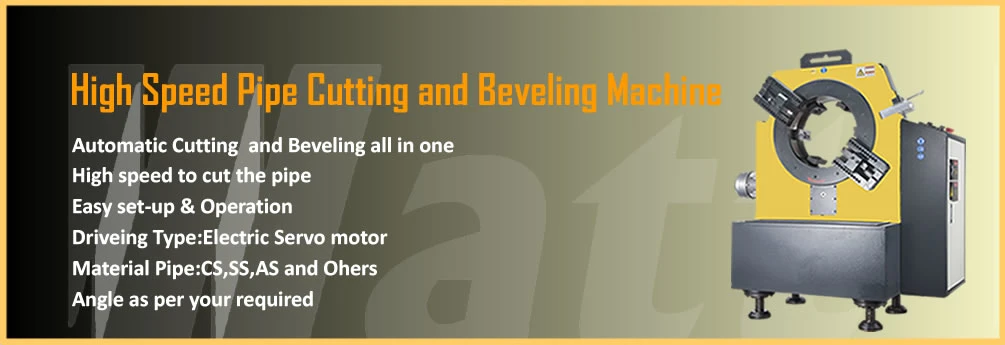

Stationary High Speed Pipe Cutting and Beveling Machine

Pipe & Flange | Cutting | Beveling | Facing | Drilling | Boring Product Description NC High Speed Pipe Cutting and Bevel;

Basic Info.

| Model NO. | K12: OD 50-325mm |

| Origin | China |

| HS Code | 846190 |

| Production Capacity | 100 |

Product Description

Pipe & Flange | Cutting | Beveling | Facing | Drilling | Boring

Product Description

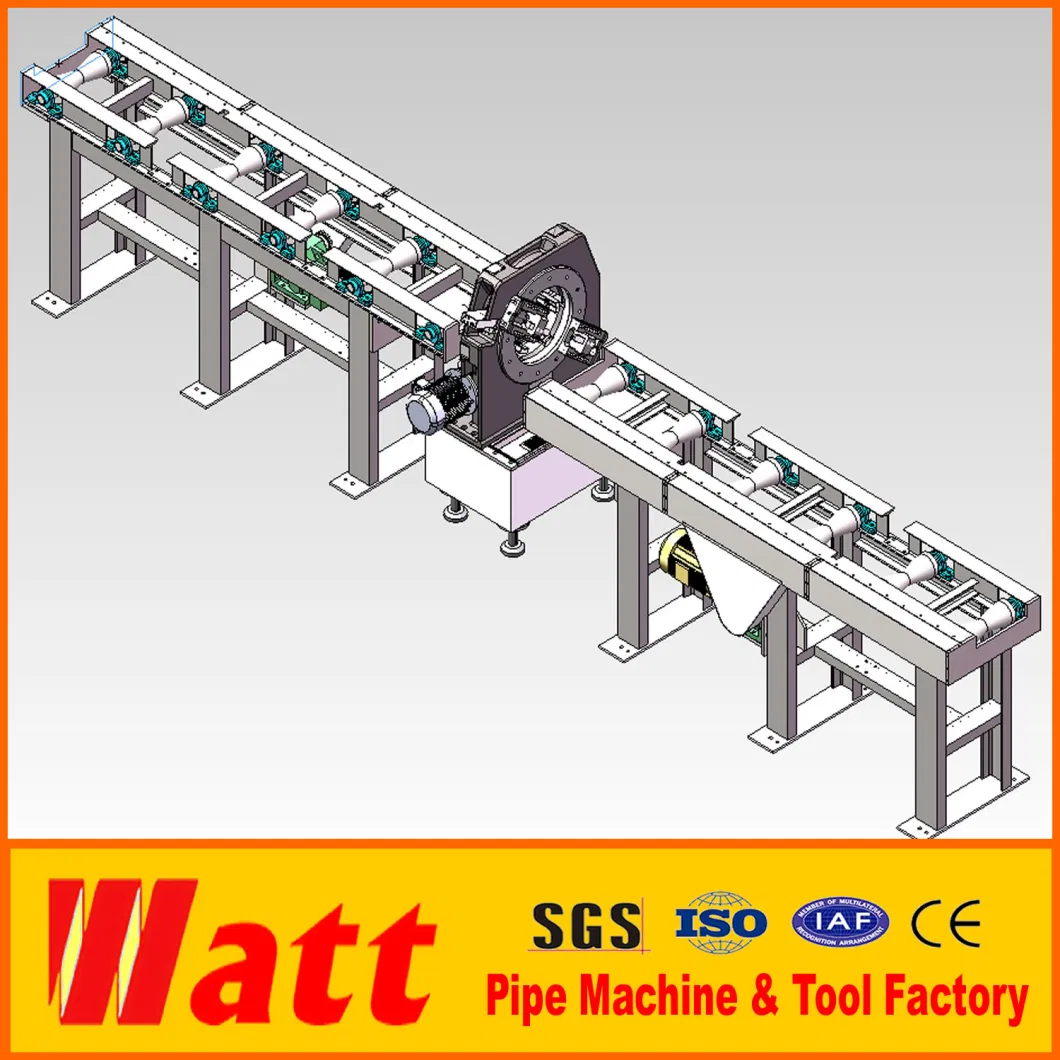

NC High Speed Pipe Cutting and Beveling Machine in workshop

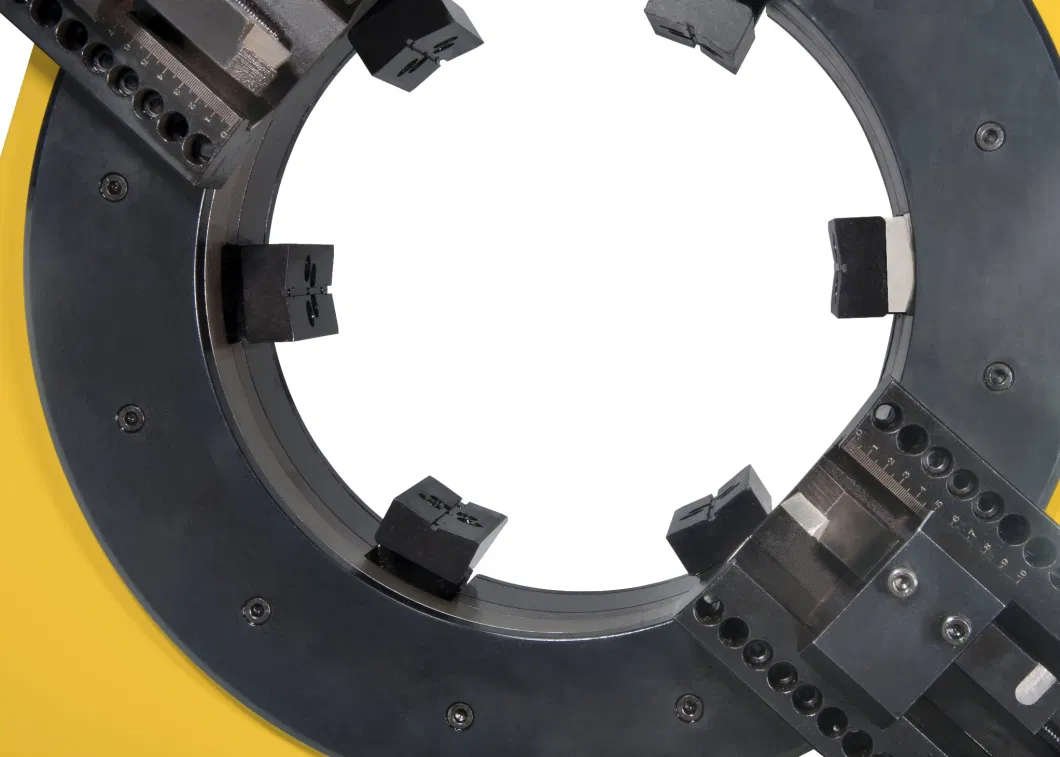

Product Show

Production Description

The series machine is ideal for all types of pipe cutting, beveling and end preparation.

An efficient pipe cutting and beveling prefabrication CNC.

Suitable for large quantity pipe cutting and beveling process.

In the workshop, It can be formulated with highly efficient logistics system, and form pipe cutting and beveling prefabricated production line.

Features:

- Cold Cutting and Beveling improves safety

- Cutting and Beveling simultaneous

- Tools feed automatically

- Fast, Precision, workshop Beveling

- Easy set-up & Operation

- Machining heavy-wall pipe from 2" up to 38"

- Suitable for large quantities of pipe cutting and beveling process.

- Built-in circulating water cooling system to improve machine and tools life.

- Host lift design, perfectly adapted to the different pipe in the same logistics system to use.

- Lifting: The lifting mechanism consists of a gearmotor through the chain and the nut on the fuselage to achieve the purpose of simultaneous lifting.

- Main drive power: drive with 2.2KW inverter motor.

- Clamping motor power:0.75-2.2KW

- Lifting motor power: 0.75-2.2KW

- Minimum working length: 200mm.

| Model | Working range | Wall thickness(mm) | Rotating speed (rpm) | |

| OD(mm) | OD(inch) | |||

| K12 | Φ50-325 | 2"-12″ | ≤30 | 0-30 |

| K18 | Φ159-480 | 6"-18″ | ≤30 | 0-20 |

| K28 | Φ325-711 | 12"-28″ | ≤30 | 0-15 |

| K38 | Φ630-965 | 25"-38″ | ≤30 | 0-10 |

Order Guide

Before you place order to us, please let us know the following information:

- Choose the right Model

- Confirm your electric power supply ( Voltage, frequency and phase)

- Confirm the beveling angel required

- Confirm the welding joint required (U, V, Double V or Compound preparation)

- Advise your pipe material ( Carbon steel, stainless steel or others)

- Other special demands about machine

- The spare parts needed

- Advise pipe wall thickness (Important)

You may also like

Send inquiry

Send now